Two packing style for Rice Vacucum packing machine

In terms of packaging effect

High vacuum degree: It can create a highly vacuum environment inside the package, effectively expel air. For some products sensitive to oxygen, such as food and electronic products, it can greatly prolong their shelf life and prevent products from oxidation, mildew and bacterial growth.

Tight packaging: Whether it is two-sided or six-sided vacuum packaging, the packaging material can be closely attached to the product. Especially for products with irregular shapes, it can also achieve a tight package without dead corners, highlighting the product appearance and enhancing the product display effect.

Moisture and dust proof: The strong vacuum sealing effect can effectively block external moisture and dust, ensuring that the product remains dry and clean during storage and transportation, which is especially suitable for some products that are prone to moisture and pollution.

In terms of production efficiency

Multifunctional integration: Integrates the functions of two-sided and six-sided vacuum packaging. One device can meet the needs of different products and different packaging forms. There is no need to equip multiple devices for different packaging requirements, saving equipment procurement costs and production space and improving equipment efficiency.

Fast packaging: It is equipped with an efficient air extraction and sealing system, which can complete the vacuum packaging process in a short time. Compared with the traditional packaging method, it greatly improves the packaging speed and can meet the needs of large-scale production.

High degree of automation: Usually equipped with an advanced control system, which can realize automatic operation, such as automatic vacuuming, automatic sealing, automatic discharging, etc. It reduces manual operation links, reduces labor intensity and improves the stability of production efficiency and packaging quality.

In terms of product adaptability

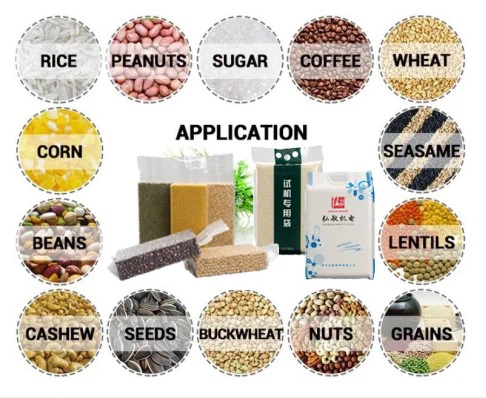

Wide range of applications: It can adapt to a variety of packaging materials, such as plastic films, composite films, aluminum foils, etc. It can also carry out vacuum packaging for products of different shapes, sizes and materials, including various forms of products such as solids, liquids and semi-solids, with strong versatility.

Customized packaging: By adjusting packaging parameters and molds, personalized packaging designs can be achieved, such as different packaging sizes, shapes, sealing forms, etc., to meet the diverse needs of different customers.

|

Model |

DCS-10F7N |

|

Power Supply |

AC380V, 5KW,Three-phase-five-wire system |

|

Working Temp. |

0-40℃ |

|

Relative Humidity |

<90% |

|

Air Consumption |

0.6 MPa ,0.36m³/min |

|

Vacuum Degree |

Relative -0.06~-0.08Mpa |

|

Packing Range |

2.5-10 kg for flat shape 0.3-5.0 kg for brick shape |

|

Packing Capacity |

300 bags/hour for flat shape 500 bags/hours for brick shape |

|

Division Value |

1g |

|

Packing Error |

±0.1% |

|

Overall Dimension (LxWxH) |

2095x1382x2459mm |

Hot Tags: two packing style for rice vacucum packing machine, China two packing style for rice vacucum packing machine manufacturers, suppliers, factory, rice packing machine thailand, 5kg rice packing machine price in india, 1kg rice packing machine, puffed rice packing machine, packing machine rice, rice packaging machine